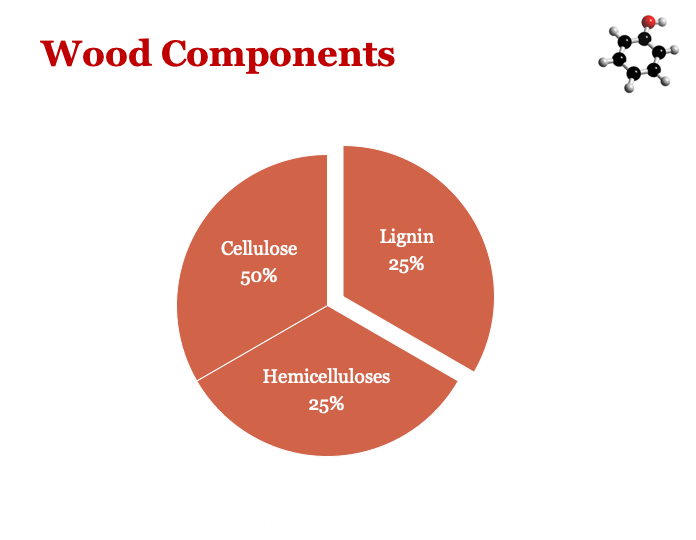

One of the important sources of organic material we can process is Lignocellulose, or more commonly known as Wood.

Wood is composed of several important and valuable chemical compounds which if separated out and refined can be the basis of a profitable and unique industry.

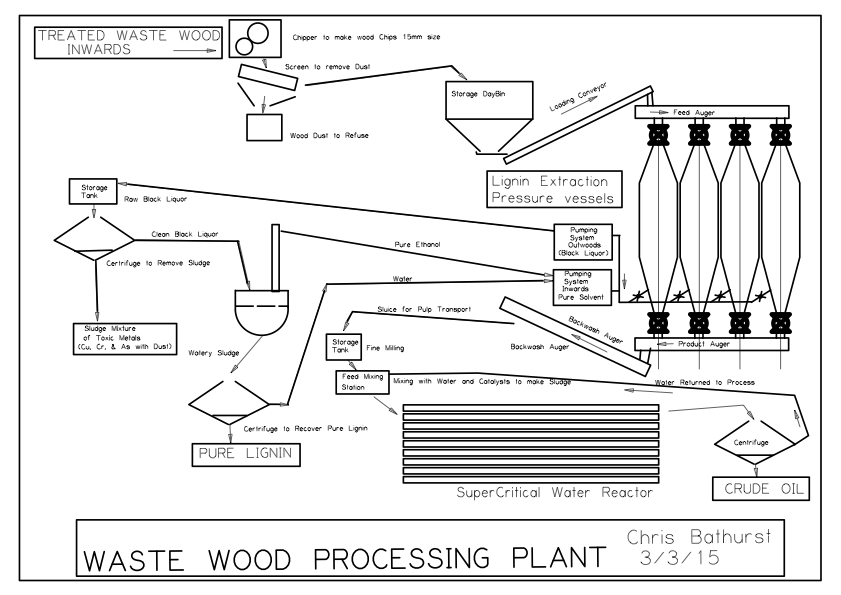

Over several years the technology to realize the necessary processes has been devised and tested here in Christchurch. The economic analyses show a high return on investment is possible from a material that is well suited to be grown profitably in the temperate New Zealand climate. Additionally we can accept used timber in any state and can also process wood treated with preservatives such as tannalised wood.

We have termed this process as WAIPIROREWA, or “washing with alcohol.”

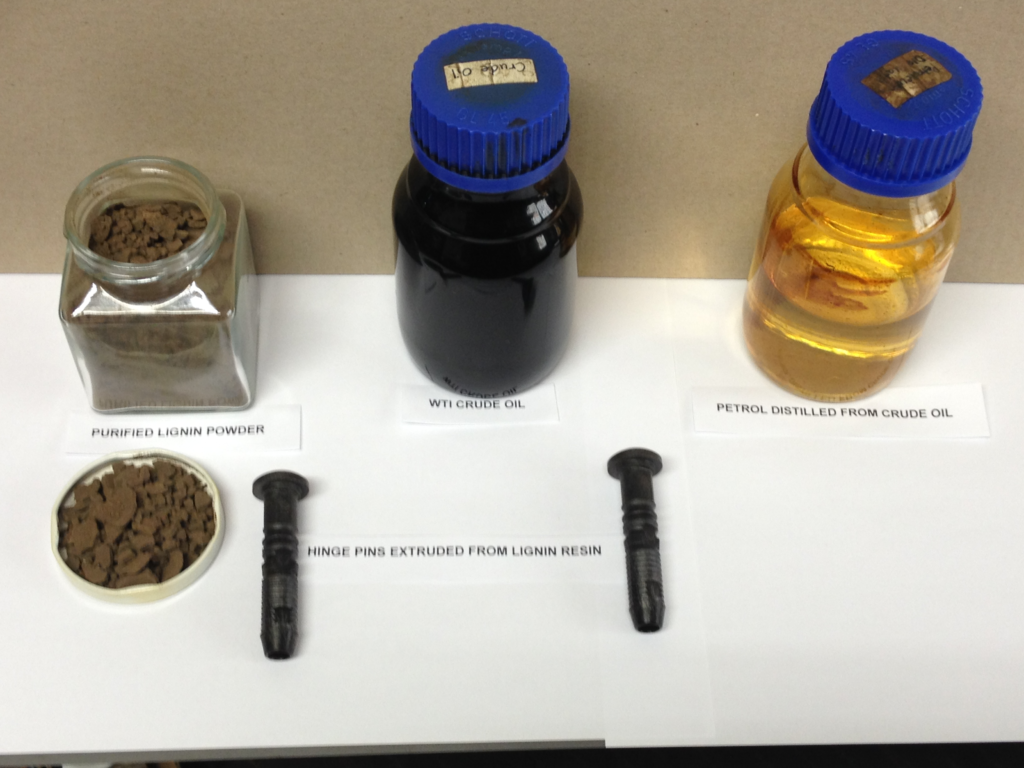

One product of the process is pure lignin, which is a brown powder resin. This can immediately be used as a feedstock for all common plastics such as for items made from polyethylene and polystyrene. In addition this lignin can be the starting point for the production of carbon fibre, paints, glues and many chemical treatments.

After removal of the lignin a cellulosic sludge remains. This can be efficiently used as a feedstock in the DIAGEN process along with the other organic wastes when making hydrocarbon crude oil, closely matching the West Texas Intermediate Standard.

This Standard is the basis for quality aviation fuels as well as petrol, diesel and all oil based products. In fact everything from agricultural chemicals to medical drugs and treatments.

Finally, when processing tannilised wood treated with the toxic chemicals of Copper, Chrome, and Arsenic, these valuable heavy metals are concentrated and precipitate out as a sludge. This sludge can then be reused for future treatment of new timber products. It will be of increasing importance as the future world construction economy becomes more dependent on processed high growth treated timbers.

This technology has been developed and tested locally in our unique pilot plant using a variety of woods from forestry timber, general timber offcuts, and treated waste timber.

Parts of this technology for dissolving the lignin in wood has been known in parts of the world for several years but was not economic due to wasted cellulosic residue. The features developed here with our unique DIAGEN technology make economic use of the whole timber material. This has made our process novel and able to be patented.